Quality is everything

Our mission at Red Arch is to deliver high quality, cost effective products and services on time every time

Whether it is an exhaust system subcomponent or a highly aesthetic carbon trim, quality is integral to everything we do. RA achieves this through the use of the APQP process, lean manufacturing and a culture of continuous improvement. During the design and development process the focus is on poka-yoke and error prevention over error detecting.

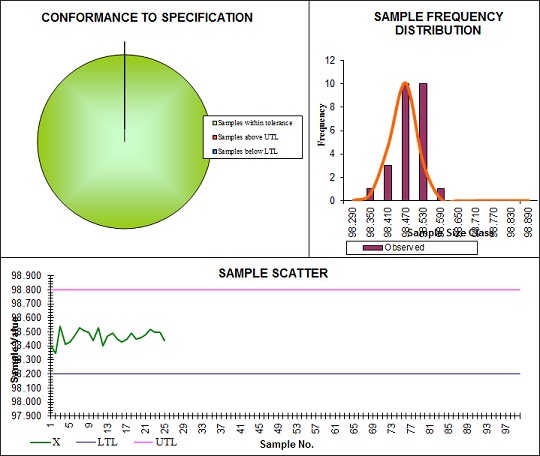

Red Arch have a wide variety of techniques to ensure the quality of our manufactured products: